Poor electricity supply is widely recognised as a key impediment to firm growth and productivity. This column finds that average reported level of electricity shortages in India reduces annual plant revenues and producer surplus of the average manufacturing plant by 5-10%. While productivity losses are smaller, shortages distort plant size distribution due to significant economies of scale in generator costs.

Low-quality infrastructure is often cited as one of the major barriers to growth in developing countries, and electricity supply is frequently rated among the top infrastructural constraints to business growth and productivity. A stark example of infrastructure failure is electricity supply in India. In the summer of 2012, India suffered the largest power failure in history – a cascading blackout that plunged 600 million people into darkness, at its peak (Yardley and Harris 2012). Even under normal circumstances, however, the Indian government estimates that shortages amount to about 10% of demand at current prices – and this has been the case for at least two decades.

By nature, firms rely on and benefit from high-quality infrastructure. Given the important role that firms play in the development process via aggregate productivity (Aghion and Howitt 2009), we ask: how do electricity shortages affect input choices, revenue, and productivity in the Indian manufacturing sector? (Allcott, Collard-Wexler and O’Connell 2015) One potential prior is that because electricity is an essential input, shortages could significantly reduce output. But for exactly this reason, firms may insure themselves against outages through alternative energy supply. The limited existing evidence (such as Alam (2013) for India, and Fisher-Vanden, Mansur and Wang (2015) for China) could support either argument.

We estimate the effects of electricity shortages across the entire country´s formal manufacturing sector; this aggregate figure is important because while policymakers are well aware that shortages are a problem, developing countries like India typically have numerous pressing policy issues. Quantifying the losses from this and other distortions helps to allocate attention to the most ‘binding’ constraints to growth, as suggested by the framework of Hausmann, Rodrik, and Velasco (2008).

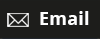

Electricity shortages in major Indian states

We collect and digitise comprehensive historical data starting in 1992 on the location and production of power plants and electricity supply shortfalls by state from annual publications of India’s Central Electricity Authority. Figures 1 shows the variation in shortages within and across five major states from 1992 to 2010: Uttar Pradesh experienced relatively high and variable shortages, in contrast to West Bengal that had consistently low and stable shortage levels for the past 20 years. Another example, Karnataka, experienced significant shortages in the early to mid-1990s, but these were reduced substantially in the mid-2000s. Gujarat had relatively reliable power supply by the end of the study period, but shortages had been more severe through the mid-2000s.

Figure 1. Variation in electricity supply shortages within and across five major states, 1992-2010

Impact on Indian manufacturing sector

We model production separately for plants with and without generators. For plants with generators, shortages act like a time-varying input tax on electricity: when grid power is not available, these plants self-generate electricity at a higher cost. Plants without generators stop production during outages -- as if facing an infinite input tax on electricity. This ‘input tax effect’ causes all plants to contract; those without generators contract substantially more. Productivity losses come from plants’ waste of non-storable inputs. For example, when textile plants shut down, (non-storable) buildings and machines continue depreciating, but (storable) thread is left on the looms without waste. For this reason, the model predicts percent revenue losses to exceed percent productivity losses.

We estimate how variation in shortages affects plants in India´s manufacturing sector using data from the Annual Survey of Industries (ASI). We use shifts in electricity supply from new power plant construction and hydroelectric power availability to capture exogenous variation in annual shortage levels. These supply shifts are not conditionally associated with agricultural output, electricity prices, or official estimates of what demand would be in the absence of shortages.

Short-term effects on revenue and productivity

Shortages have a positive but economically small effect on energy input costs for plants with generators: a 10 percentage-point increase in shortages increases average fuel expenditures by 1.8% of revenues, but this additional expenditure is seen alongside a decrease in grid electricity purchases. Average revenues decrease by 11%, which is largely explained by decreases in material inputs by a comparable amount. Since materials outlays comprise 70% of revenues on average, revenue productivity is reduced only a fraction of the reduction in revenues.

We apply the production function model using distributions of capital and productivity among plants in the ASI to simulate the effects of shortages1. We simulate that the assessed level of shortages reduced producer surplus2 by 9.5%, revenues by 5.6%, and productivity by 1.5% for the average plant in 2005.

Long-term effects on industry composition

As the estimates described above are identified by annual variation in supply shifters, they capture primarily ‘short-run’ effects of shortages, that is, holding constant decisions such as generator capital stock and plant entry and exit. To shed light on long-run effects, we briefly study the association between plant characteristics and the average shortages in the two years preceding plant entry. We find suggestive evidence that plants in electricity-intensive industries are less likely to enter when shortages worsen, implying that shortages may have deeper effects on the composition of Indian industry.

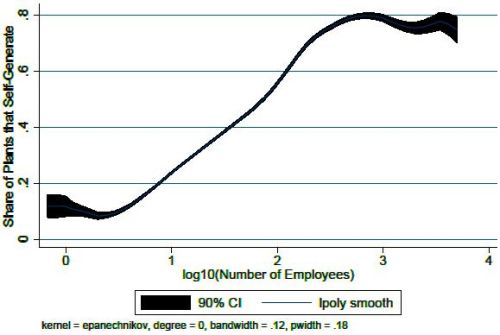

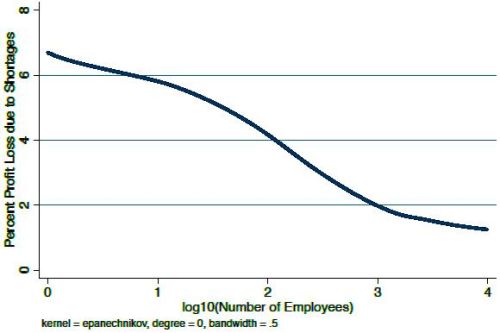

Self-generation of electricity and plant size

The simulations allow us to provide two additional insights. First, shortages more severely affect plants that do not have generators, and generator costs have significant economies of scale (Figure 2). We simulate that as a result, variable profit losses average 2-3 times larger for small plants compared to large plants (Figure 3) – pointing to one potential factor in explaining India’s bimodal plant size distribution.

Figure 2. Self-generation of electricity and plant size

Figure 3. Profit losses due to electricity shortages and plant size

Interruptible electricity contracts

Second, we simulate the effect of interruptible electricity contracts. These contracts offer plants reduced retail prices in exchange for accepting more frequent power outages, efficiently allocating shortages to plants that can best deal with them. Our simulations show that if implemented nationwide, they could reduce producer surplus losses by more than an order of magnitude. While interruptible contracts do require additional physical infrastructure to implement, they may be a useful partial solution in the Indian context because due to political barriers that have prevented other market reforms to reduce shortages.

Conclusion

While shortages might substantially affect manufacturing output in the short-run, our estimates explain little of the manufacturing productivity gap between India and more developed countries. An alternative contract regime would allow manufacturers to sort into allocatively efficient shortage levels, substantially reducing aggregate losses from shortages - requiring neither large-scale energy sector reforms nor long-term elimination of shortages.

This article originally appeared on VoxEU.

Notes:

- Following Todd and Wolpin (2006), we validate the structural model using the agreement of the model´s predicted effect magnitudes with those of the reduced-form results. The simulated effects and model estimates are statistically indistinguishable, which builds confidence that the estimates are reasonable and the model captures the first-order effects of shortages.

- Producer surplus is defined as the difference between the amount the producer is willing to supply goods for and the actual amount received by him when he makes the trade.

Further Reading

- Aghion, P and P Howitt (2009), The Economics of Growth, MIT Press, Cambridge, Massachusetts.

- Alam, M (2013), ‘Coping with Blackouts: Power Outages and Firm Choices’, Yale University Working Paper.

- Allcott, Hunt, Allan Collard-Wexler and Stephen D O’Connell (2016), “How Do Electricity Shortages Affect Industry? Evidence from India”, American Economic Review, 106(3):587-624.

- Fisher-Vanden, Karen, Erin Mansur and Qiong (Juliana) Wang (2015), “Electricity Shortages and Firm Productivity: Evidence from China´s Industrial Firms”, Journal of Development Economics, Vol. 114, Pages 172-188.

- Hausmann, R, D Rodrik, and A Velasco (2008), ‘Growth diagnostics’, in N Serra and J Stiglitz (eds.), The Washington Consensus Reconsidered: Towards a New Global Governance. Available here.

- Yardley, J and G Harris (2012), ‘2nd Day of Power Failures Cripples Wide Swath of India’, New York Times, 31 July 2012.

25 November, 2016

25 November, 2016

Comments will be held for moderation. Your contact information will not be made public.